|

|

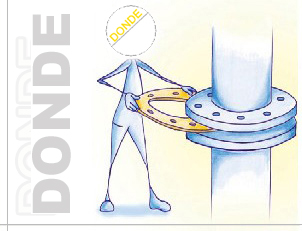

Spiral wound gasket production process and equipment

In

the present seal, metal spiral wound gasket with

excellent elasticity, high temperature, high

pressure, low temperature and other characteristics,

has become a very wide range of applied seal.

Especially suitable for uneven loading, relaxation

and easy access together, cyclical changes in

temperature and pressure of the occasion, is the

main flange gasket. In the petrochemical pipelines,

mechanical seals, shipbuilding, metallurgy,

aerospace and other industries widely. In

the present seal, metal spiral wound gasket with

excellent elasticity, high temperature, high

pressure, low temperature and other characteristics,

has become a very wide range of applied seal.

Especially suitable for uneven loading, relaxation

and easy access together, cyclical changes in

temperature and pressure of the occasion, is the

main flange gasket. In the petrochemical pipelines,

mechanical seals, shipbuilding, metallurgy,

aerospace and other industries widely.

It

is due to the importance of

Spiral Wound Gaskets, so its quality is good or bad for the sealing device has a

great impact. If the gasket to poor quality, or even

cause damage to the sealing device and operator

hazards. Now domestic manufacturers of spiral wound

gaskets generally poorly equipped, poor technology,

spiral wound gasket relatively low level of

production, the quality produced by the spiral wound

gasket is not stable enough. In addition to

equipment problems, as well as the structural

parameters of spiral wound gasket is no uniform

process parameters of research and analysis, most

manufacturers are based on their experience to

production, such as wrapping and packing with a flat

strip width, strip forming the angle and width of no

uniform requirements, these details of the problem

is the appearance of spiral wound gaskets and

quality reasons. In addition, the production of

spiral wound gasket is not high degree of

automation, manual operation is not only

inefficient, difficult to guarantee quality gaskets,

such as in the winding process, the pad width size,

strip tension force and shear force were not

automatically control, size, manual measurement,

these factors seriously affected the gasket. With

the rapid development of industry and the increasing

requirements on the parameters of the increasing

demand for high-quality spiral wound gasket, spiral

wound gaskets of process parameters and equipment,

it has very important significance. It

is due to the importance of

Spiral Wound Gaskets, so its quality is good or bad for the sealing device has a

great impact. If the gasket to poor quality, or even

cause damage to the sealing device and operator

hazards. Now domestic manufacturers of spiral wound

gaskets generally poorly equipped, poor technology,

spiral wound gasket relatively low level of

production, the quality produced by the spiral wound

gasket is not stable enough. In addition to

equipment problems, as well as the structural

parameters of spiral wound gasket is no uniform

process parameters of research and analysis, most

manufacturers are based on their experience to

production, such as wrapping and packing with a flat

strip width, strip forming the angle and width of no

uniform requirements, these details of the problem

is the appearance of spiral wound gaskets and

quality reasons. In addition, the production of

spiral wound gasket is not high degree of

automation, manual operation is not only

inefficient, difficult to guarantee quality gaskets,

such as in the winding process, the pad width size,

strip tension force and shear force were not

automatically control, size, manual measurement,

these factors seriously affected the gasket. With

the rapid development of industry and the increasing

requirements on the parameters of the increasing

demand for high-quality spiral wound gasket, spiral

wound gaskets of process parameters and equipment,

it has very important significance.

Based on this, I optimized the optimum gasket and structural

parameters, to develop the best technical standards,

development and production of a special gasket CNC

equipment, including cutting machine, winding

machine, bending machine, Central , ring milling

machine. Gasket in the core function of the process

is winding, winding machine of our company high

degree of automation, feed, size, strip tension

force can be a dedicated controller through my

company automatic control and display, large size

can be Automatic welding and non-punch wound,

production efficiency is greatly improved, while the

production of high quality out of pads, in line with

various standards, will be the future trend of the

production of

Spiral Wound Gasket. At the same time as the market demand, the company will

also upgrade equipment, such as automatic ejection. Based on this, I optimized the optimum gasket and structural

parameters, to develop the best technical standards,

development and production of a special gasket CNC

equipment, including cutting machine, winding

machine, bending machine, Central , ring milling

machine. Gasket in the core function of the process

is winding, winding machine of our company high

degree of automation, feed, size, strip tension

force can be a dedicated controller through my

company automatic control and display, large size

can be Automatic welding and non-punch wound,

production efficiency is greatly improved, while the

production of high quality out of pads, in line with

various standards, will be the future trend of the

production of

Spiral Wound Gasket. At the same time as the market demand, the company will

also upgrade equipment, such as automatic ejection.

Customer needs is our driving force, welcomed the new and old

customers to negotiate inquiry.>>The

End Customer needs is our driving force, welcomed the new and old

customers to negotiate inquiry.>>The

End

|